Decrease Fuel Costs

Year Round

Longer, More Effective Ammonia Control Lowers Fuel Costs

Poultry house fuel costs can quickly rob the bottom line. Applying PLT® to control poultry ammonia decreases fuel usage – even in the summer. In fact, a summer air quality survey of 251 broiler houses showed that 98% of houses treated with PLT had ammonia levels below 25 PPM AND saw fuel savings of 68% compared to farms using no litter treatment.

Lower Fuel Costs in Every Climate

Of course, winter poultry house fuel costs are more substantial for every grower and so is the potential to save. Applying PLT at an application rate sufficient for your litter’s ammonia challenge can increase your profit by decreasing fuel costs.

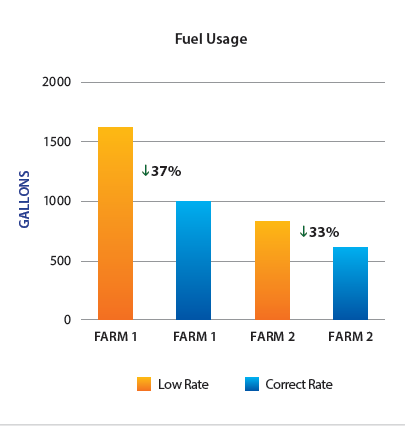

A winter study was done on two farms – one in the north (colder climate) and one in the south (warmer climate) – to see how much fuel could be saved by applying PLT at a rate that was sufficient to meet the litter’s ammonia challenge.

The savings of 600 gallons of propone on farm 1 at a fuel rate of $2 per gallon put $1,200 back in the pocket of that grower. On farm 2, a savings of 300 gallons of propone saved $600 that flock.

THE CORRECT OR SUFFICIENT RATE OF PLT DECREASED FUEL USAGE BY 37% AND 33%, RESPECTIVELY

Learn More About PLT

Learn more about PLT and how to identify the correct rate for your litter.